As project professionals, we want to be part of making jobs successful.

What constitutes success? Well, I think we can all agree that it’s a combination of: constructing a quality product safely, ensuring it’s delivered on time and on budget, looking after the environment, and producing an end product that is fit for purpose for all stakeholders.

So why do so many projects fail, and why does this seem to be increasing as time goes by? It’s something that I’ve been thinking about over the last few years, as I’m sure most of us in the industry have.

There is no one problem. However, I believe there’s an overarching framework of thinking about a project using complexity theory that can open our eyes to what’s going on.

The current state of projects

I’ll use project costs as a basis for my explanations because it’s the most measurable, but these concepts can be applied to all the project outcomes listed above.

To talk about these projects, let’s take a journey from building an estimate, to designing the structure, to building the works. (Note: The below is an oversimplified explanation of how a project estimate, design and execution occurs for simplicity.)

When it comes to building an estimate for a project, we start by imagining the resources, time and cost that go into each component of the works. For example a set crew and production rate is “known” for drainage pipe install and quantities are fed into an estimate to give a lineal m price.

If our project involves building a road, we’ll start by estimating the cost of design, followed by the cost of activities such as site clearing, asset relocation, earthworks, and pavement installation.

Generally, this is completed through first principles pricing and using market rates for resources.

For certain items or activities, we may use historic rates, but only for those that are replicable or repeatable.

As an industry, we tend to disregard previous projects’ costs as somewhat irrelevant. We put very little effort into capturing costs for completing different activities. If we do capture the costs, we won’t capture the corresponding productivities for the works, rendering the data only half-complete.

Each project is unique – we aren’t making widgets in factories and it’s not as simple as recording what you made the last 1000 widgets for and multiplying this forward. We build structures in dynamic environments that are different from project to project. This seems to translate into a reluctance to capture meaningful project production data – we can’t quite see what we’d use it for.

Because we can’t simply replicate past project performance from job to job, we discount empirical data (actual data) completely and build estimates using our past experience and industry knowledge.

Once we have our “bottom up” estimate, we add these items together.

Cost of road = earthworks + drainage + pavement + asphalting + overhead + R&O.

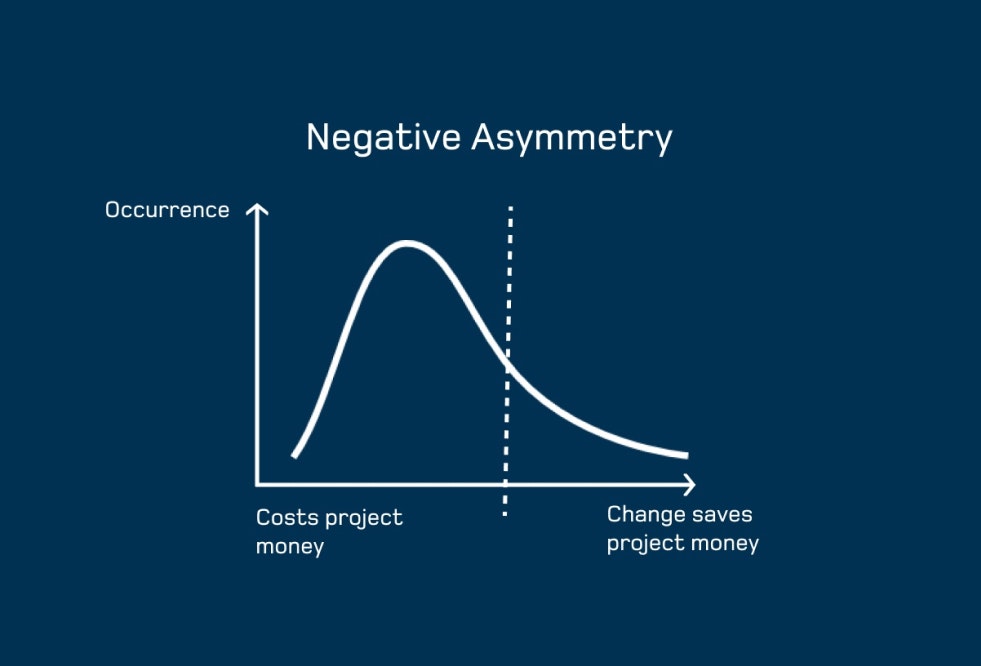

We may, if we’re feeling diligent, add up any risk and opportunity values that we can think of, weigh these, and add them to our estimate. Some projects use statistical techniques such as Monte Carlo analysis also. These still rely on the quality of the inputs placed into the models.

With some differences, this is how we estimate our projects, from small to very large projects.

Generally, little empirical data is considered in this process.

How predictable are your projects?

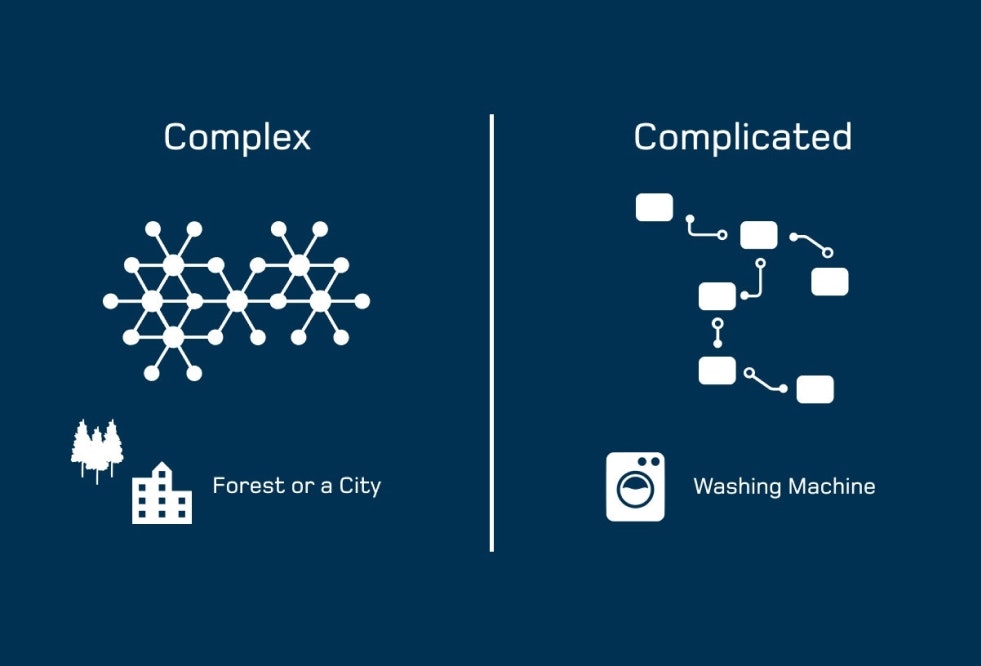

Executing the work is where things get interesting. Projects involve a number of interdependent moving parts. Some jobs are simple, some are complicated and others are complex. The more interconnected elements, the more complex the project.