Why is temporary works so important?

At FSC, we design and construct complex infrastructure projects, so we have a deep understanding of the intricacies of projects both great and small. From a design perspective, the risks of temporary works vs permanent works is assessed as follows.

Permanent Works Design:

Design Load Case: Ultimate Load Case (e.g. Extreme Wind, Earthquake, etc.)

Likelihood = Rare

Factor of Safety >2.0

Temporary Works Design:

Design Load Case: Serviceability Load Case (e.g. construction equipment, crane loads, piling rigs, etc.)

Likelihood = Certain

Factor of Safety can be ≤1.5

Put simply; temporary works is implemented in a controlled environment for a much shorter period of time than permanent works, and therefore is designed closer to the limit. Likewise, the construction of complex infrastructure involves the staged assembly that, unless done carefully, can result in loading elements in a manner not contemplated by the original designer.

Temporary works at FSC

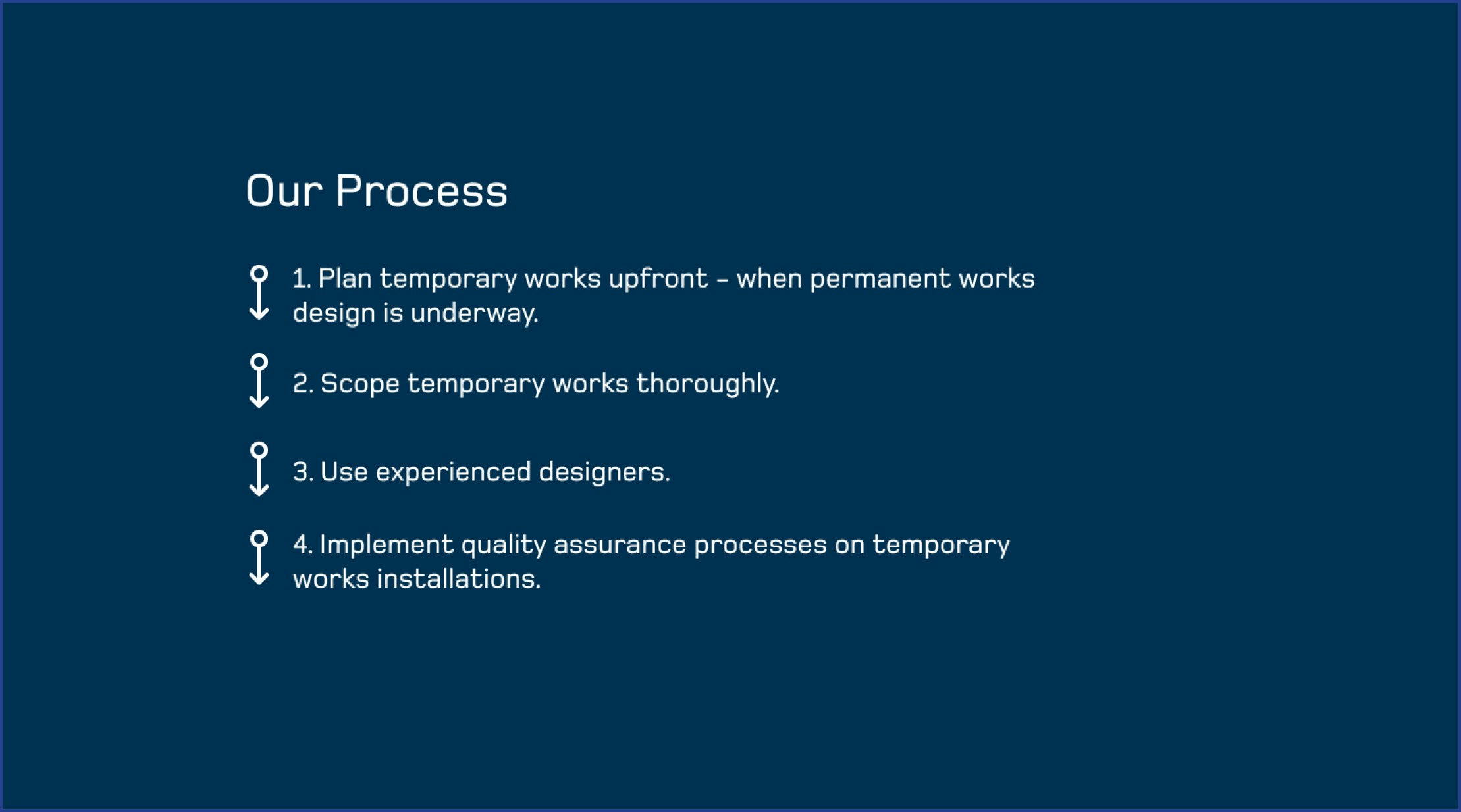

Temporary works need to be considered upfront and fed into the design of permanent works. Early design engagement between the temporary works team and permanent works designers is crucial to the development of the design and understanding each parties roles and responsibilities. In doing so, we ensure a project’s safety and constructability resulting in a project that is delivered on time and budget.

Temporary Works design briefs are fundamental inputs – a poor design brief will result in redesigns and oversights that could potentially lead to injuries, budget blowouts and in some cases, lawsuits. A properly detailed design brief has to be produced by a competent engineer and reviewed thoroughly by the temporary works team to ensure all necessary assumptions are validated. A ‘back briefing’ is usually the best way to ensure that all parties’ expectations are aligned. Once constructed, a thorough inspection and sign off prior to the loading and unloading of temporary works are important steps that need qualified and competent people involved.

Having experienced engineers involved is critical as while every project is unique, most of the process, design and actual works aren’t. Engaging FSC can result in big time and cost savings through efficient design, design management and either re-use or adoption of methodologies from previous projects.

Approval for temporary works can potentially be a lengthy process, so plan early to avoid delays on your project and ensure your client’s requirements are well understood. Importantly, don’t forget to review the design assumptions and establish quality assurance (QA) of temporary works. QA documentations, routine inspections and maintenance are critically important to avoid oversights and worksite incidents.